Powerful Sandblasting for a Flawless Finish in Missoula, MT

At Clark Industrial, Inc., we provide professional sandblasting services designed to prepare and restore metal surfaces for long-lasting performance. Based in Missoula, MT, and serving Granite, Powell, Lake, Sanders, Mineral, and Ravalli counties, our team ensures every project is completed with precision and care. Whether you need rust removal, surface preparation for coating, or restoration of structural metal components, our sandblasting services help your metal look and perform its best.

Call

406-273-6030 today to schedule your sandblasting project or request a quote online.

Why Sandblasting Matters

Sandblasting is more than just cleaning metal—it’s a critical step in ensuring durability, safety, and aesthetic appeal. By removing rust, old paint, and contaminants, sandblasting creates a smooth surface that allows coatings, paint, or powder finishes to adhere properly. This process extends the life of your metal products, protects against corrosion, and ensures your structural components meet industry standards.

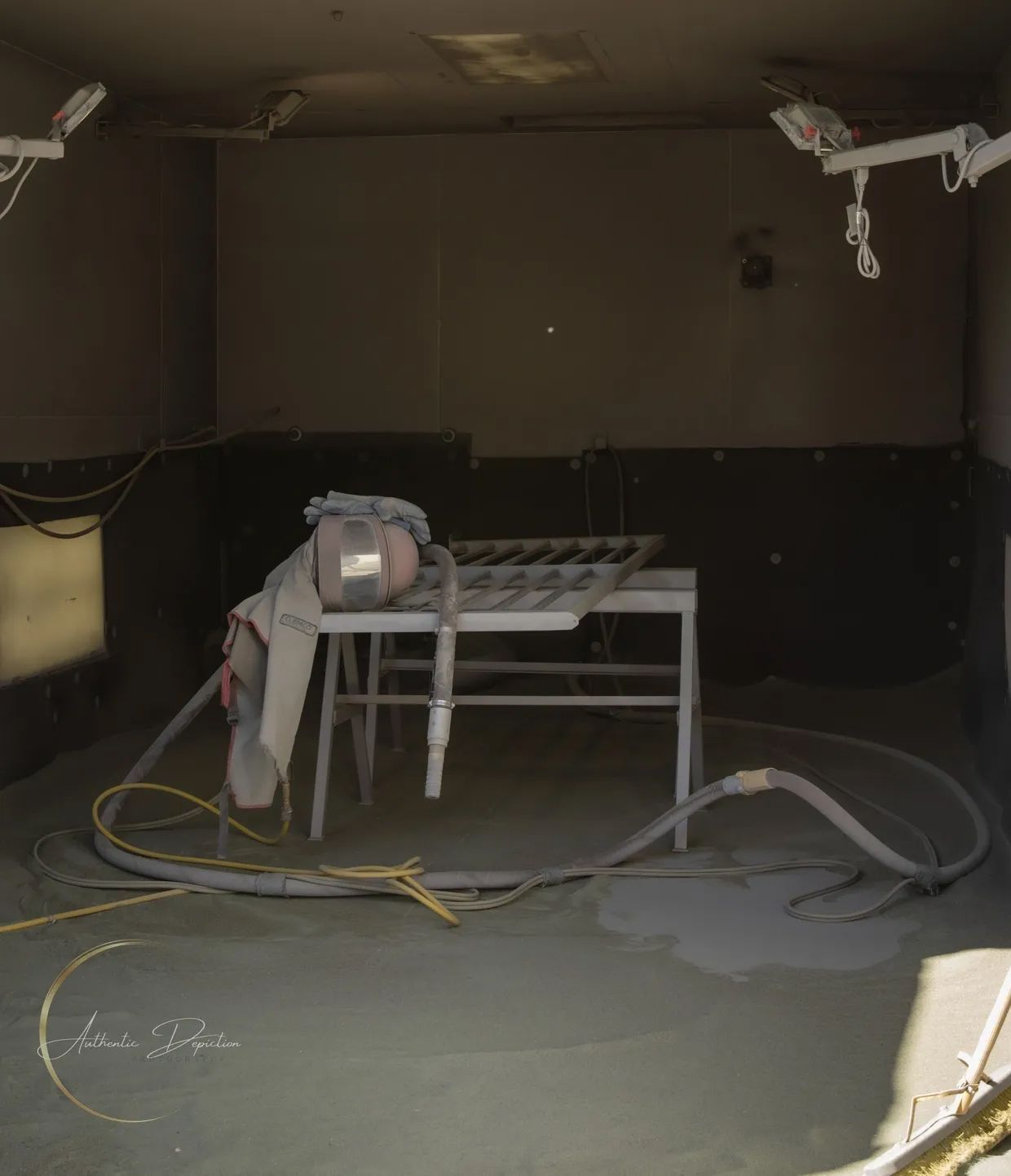

At Clark Industrial, Inc., we use advanced sandblasting equipment to handle projects of all sizes—from small components to large industrial structures—with precision and consistency.

Our Sandblasting Capabilities

Our Missoula-based facility is equipped to tackle a wide range of sandblasting projects. Here’s what we offer:

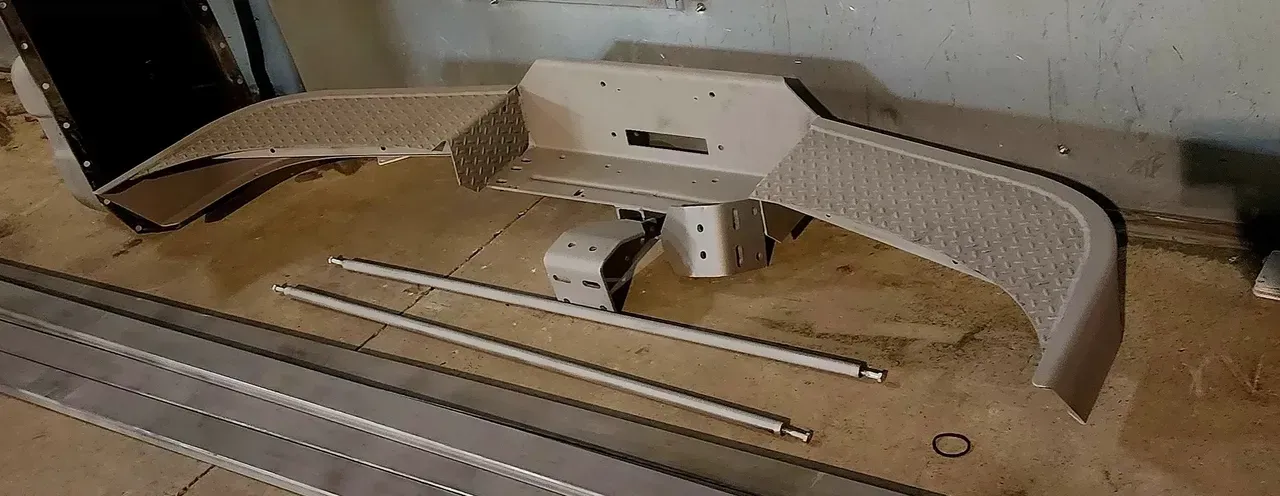

- Industrial Sandblasting: Preparing structural steel, machinery parts, and industrial components for coating or painting.

- Residential Sandblasting: Rust removal and surface prep for railings, fences, gates, and other home metalwork.

- Large Part Sandblasting: Our equipment accommodates larger items, ensuring every surface is evenly treated.

- Surface Preparation for Coating: We prepare surfaces for powder coating, paint, or galvanization, ensuring maximum adhesion and a flawless finish.

Our skilled technicians combine industry knowledge with hands-on expertise, guaranteeing every project meets your specifications and industry best practices.

Benefits of Choosing Clark Industrial, Inc. for Sandblasting

Working with our team gives you the advantage of:

Experienced Professionals: Decades of metalworking experience to ensure consistent results.

Precision Equipment: Modern sandblasting tools capable of handling small and large projects.

Durability: Properly prepared surfaces mean coatings last longer and metals stay protected.

Local Expertise: Serving Missoula, MT, and nearby counties with reliable, responsive service.

Whether you’re a homeowner, contractor, or industrial client, we tailor our services to your unique needs and provide guidance on the best preparation techniques for your project.

Sandblasting for Residential and Commercial Projects

At Clark Industrial, Inc., we cater to both residential and commercial clients. Homeowners can benefit from our walk-in services for powder coating and sandblasting prep, while commercial clients enjoy full-service project support. From small decorative items to large structural components, we provide professional guidance and superior workmanship for every metal surface.

AISC Certified and Trusted Professionals

As an AISC Certified Fabricator, Clark Industrial, Inc. maintains the highest standards for all our metalwork processes, including sandblasting. This certification ensures that every project is completed with strict adherence to safety, quality, and industry best practices. When you choose our team, you’re partnering with experts committed to precision and accountability.

Service Areas

We proudly provide professional sandblasting services throughout Missoula, Granite, Powell, Lake, Sanders, Mineral, and Ravalli counties, along with nearby areas. No matter where your project is located, we ensure timely, reliable service.

Common Questions About Our Sandblasting Services

What Metals Can You Sandblast?

We sandblast a variety of metals, including aluminum, carbon steel, and stainless steel, preparing them for coatings or finishing.

Can You Handle Large or Heavy Parts?

Yes. Our equipment is designed to manage both small components and larger structural pieces.

Do You Offer Residential Sandblasting Services?

Absolutely. We work with homeowners on decorative railings, gates, fences, and other custom metalwork.

Is Sandblasting Safe for Delicate Materials?

Yes. We adjust our techniques and equipment settings to ensure delicate items are cleaned without damage.

Do You Provide Surface Preparation for Powder Coating?

Yes. Proper surface prep is essential for coating adhesion, and we specialize in preparing metals for powder coating, paint, and galvanization.

Call 406-273-6030 for professional sandblasting and surface prep.